Last Friday, Alex (our framer and also our landlord!) got his first delivery of framing materials, and he and his crew have been busy. After 4 days of work, most of the first floor framing is complete. It’s exciting to see the house start to take shape!

We’re using framing materials that are as green as possible. The floor joists are TJI’s (Truss Joist I-joists), a fabricated product made from wood chips, minimal actual lumber, recycled materials, and advanced adhesives. You can see an article about them here. TJI’s are lighter, stronger, straighter, and more ecological than standard 2×12 construction lumber.

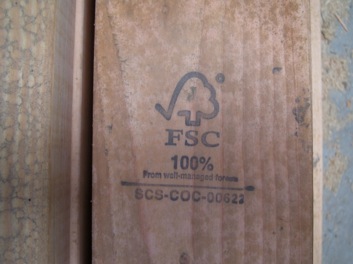

The wood that we are using for studs, stringers, etc. is certified by the Forest Stewardship Council, ensuring that it was responsibly harvested. This has added some extra cost to the framing materials, but it’s also in alignment with our vision to build a sustainable, energy-efficient and ecologically responsible house.

Framing materials are piled everywhere. Here are pics of the left garage, looking through the garage door into the center of the 1st floor, and a close-up of the stairway and elevator shaft framing in the center. You can see the pit at the bottom of the elevator shaft in the right-hand photo, bottom left corner. The platform in this photo is the landing for the stairs going up to the 2nd floor, and it is 6’ above the floor. By the way, the ceilings on the 1st and 2nd floors will be pretty high, about 11-1/2’.

Notice that the wall materials are fabricated out of wood chips also. This is another way to use recycled and low-impact lumber products. Like plywood, this wallboard is stronger than simple lumber…although it is really heavy and dense!

From the outside, you can see how each entry is full of framing materials. You can also see a steel box full of concrete debris, with cables up to…what in the hell is that?

This is actually the scene that greeted me when I arrived during lunch today. Brent’s crew is here completing the backfill behind the retaining wall. They’ve brought in a crane, which is roaring as it moves boxes full of rock, concrete debris, and dirt up behind the wall. The space behind the top of the wall is being filled in before construction of the v-ditch that will provide drainage, and a big space behind the right wing wall is getting filled also. This is yet another added expense caused by our original contractor’s over-excavation. Sigh.

Here you can see some details. Brent is using his Bobcat skip-loader to scoop up and dump dirt into the box, about 1 yard at a time. The crane lifts the box up onto the wing wall, and Brent’s crew unfastens the cables on the front side of the box. Then the crane operator lifts the box, tipping the contents into the space behind the wall. Of course, the crew then has to shovel all the material up into place, establishing the proper slope behind the wall.

Oh, by the way, it rained this morning. It’s early for the rainy season to start in the San Francisco area, but it feels like a warning shot. We may have a wet winter. Of course, we were blessed with a very dry winter last year while excavating the foundation, so we can’t complain. But we do have to hurry. The real rainy season usually begins in late October or early November, and we would like to have the drainage complete, framing done, windows installed, roofing complete, and exterior stucco finished before it gets really wet.

We have one other piece of good news today. The final mechanics lien on our property has been released, so our bank will go ahead and process draw requests against our construction loan again. Thank god. Our cash position was getting pretty scary.

(Learn from our mistake! A signed lien release does not release the lien. The holder of the lien has to provide a notarized, signed release to the agency where the lien was filed, and pay a registration fee to get the release processed. We had to hound our original contractor, make dozens of phone calls, have our lawyer contact their lawyer, and finally threaten lawsuit before they provided the release. I got it via FedEx this morning, and took it down to the County of Marin Recorder to register it myself. The legal mess with the original contractor has now been completely resolved.)

Sorry, the comment form is closed at this time.